welcome to

The New Wave: Feature-Rich Products

Where is

the flowmeter market headed in the next few years?

Will suppliers continue to battle over price?

Will the battle continue over new-technology vs. traditional

technology flowmeters? Will

Coriolis and ultrasonic continue to expand their market presence in both

gas and liquid applications?

While all the above are true, I also believe that the next wave will be a battle over who has the most feature-rich products. Why is this the case?

Customers

are looking for more capability from their flowmeters.

They are looking for more information about the process.

They want higher accuracy, greater rangeability, the ability to do

better diagnostics, less maintenance, and higher reliability.

Even though some of these capabilities may increase the purchase

price of a flowmeter, they will in many cases save money over the life of

a flowmeter. Companies that

offer more features that satisfy the needs of end-users will be rewarded

with greater sales.

What this

means for flowmeter companies is that there is no substitute for spending

money on research & development.

Some of the most innovative products that have come out recently

are the result of substantial amounts of internal research &

development. These include:

- GE Panametrics GC868 clamp-on flowmeter for gas

- Emerson Rosemount’s 3051S pressure transmitter

- Foxboro’s CFT50 digital Coriolis flowmeter

- Krohne’s UFM 3030 liquid ultrasonic flowmeter

All these

products build in additional features to provide greater capability and to

address previously unsolved measurement problems.

The GC868 brings clamp-on measurement to an area dominated by

inline full-bore meters—gas flow measurement.

The 3051S provides greater accuracy and stability than was

previously possible in pressure measurement.

Foxboro’s digital Coriolis flowmeter was created to solve

problems associated with accurate measurement of two-phase flows.

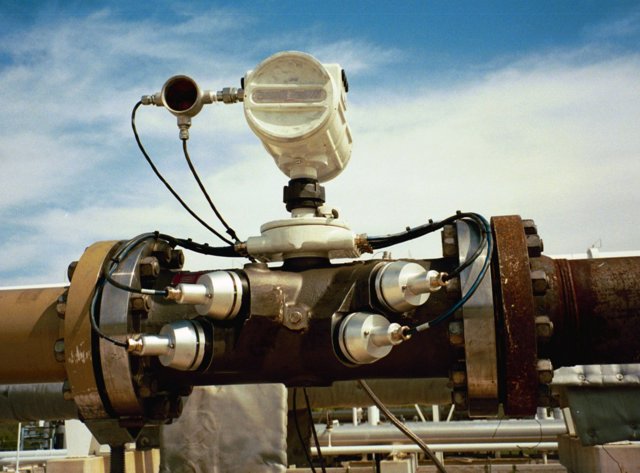

And Krohne’s UFM 3030 meter is designed as a three-beam meter to

bring the advantages of ultrasonic flow measurement to liquids where

custody transfer is not required.

In the

late 1990s, a lot of companies had to spend money on Y2K issues, and many

instrumentation companies were devoting their research dollars to

developing fieldbus products. Even

though the fieldbus issue has not been completely resolved, it seems clear

that we are going to have to live with multiple fieldbuses.

At least the path is clearer today than it was several years ago.

I used to

say that, with Y2K and the fieldbus issue largely behind us, companies

will begin allocating more money to developing and improving sensors, an

area that has been neglected over the past ten years.

While I still believe that, I see now that the issue is broader

than sensor development. Besides

improving their sensors, companies are also improving their software, the

materials of construction, their flowmeter liners, and their fundamental

technologies. There are in fact a number of different ways in which

flowmeters and other field devices are being improved.

The good news is that these improvements have nothing to do with

communication protocols, but have everything to do with building better

and more reliable flowmeters.

This brings us back to the original idea of building feature-rich products. Feature-richness comes in a variety of flavors. It may involve digital signal processing (DSP), which has been used to enhance the performance of vortex flowmeters and make them less susceptible to vibration. It may involve adding extra transducers to an ultrasonic flowmeter, or using ceramic ball bearings to make turbine flowmeters more reliable. These are all examples of improvements that have been made as a result of research & development, and they are part of the new wave of feature-rich products.