welcome to

Note: This article is excerpted from the Market Barometer, Q3/Q4 2006

Hybrid automobiles make a lot of sense. Basically, they combine two distinct technologies in order to achieve maximum efficiency. So why not apply the same engineering process to the design of open channel flowmeters, rather than attempting to utilize a single flow measurement technology for applications encompassing a broad spectrum of consistently changing conditions, i.e., low flows, high flows, surcharges, reverse flows, stagnation, and non-uniform flow profiles?

As with the hybrid automobile, choose the technology that will produce the most cost efficient and accurate results for a given situation. It already is common knowledge that low flows are best measured by a combination comprised of a flume and an ultrasonic level sensor. High flows, reverse flows and instances of stagnation are best measured by combining a pair of transit time velocity sensors with an "above the flow” ultrasonic level sensor. Surcharge events can be monitored and detected by utilizing the same pair of transit-time velocity sensors in conjunction with an additional ultrasonic level sensor placed at the highest point in the manhole. Non-uniform flow conditions, frequently encountered during storm events, are capable of being accurately monitored by a multiple pair of transit-time velocity sensors in combination with single or dual ultrasonic level sensors.

Presently, single technology flow measurement solutions are only accurate within a specific or prescribed range of conditions. If conditions change, the stated accuracy rating of these instruments is no longer valid. For example: A flume/level combination, besides being expensive and time consuming to install, will lose its 5% accuracy rating once submerged conditions are reached. "Bottom Sitting" Doppler/pressure cell combinations suffer from inherent problems brought on by silt build-up, fouled sensors, non-uniform particle distribution and velocity profile variations. Additionally, low or dry day flow conditions (below 3”), will present measurement problems for the Doppler sensor. Surface detecting radar flow measurement devices solve the maintenance problem of fouled sensors, but besides carrying a heavy price tag, also require in-situ flow profiling due to the fact that they are only capable of capturing the fluids velocity on the surface of the media being measured. According to the U. S. Bureau of Reclamation Water Measurement Manual, “open channel flow measurement is complicated by the potential errors introduced by a variable water surface."

So when it comes to monitoring open channel sewers and outfalls, an "accurate and virtually maintenance-free under all conditions" hybrid flowmeter makes a lot of sense. How else could one gather consistent and accurate flow data under low, interim, high, reverse, stagnant and non-uniform conditions?

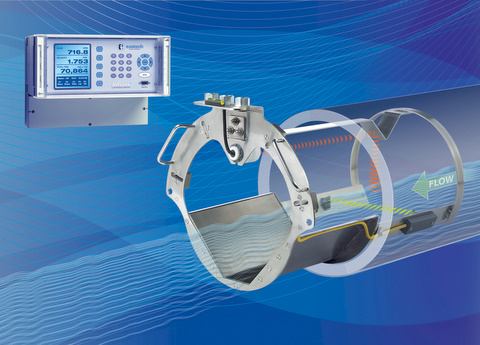

Eastech

Flow Controls has introduced an open channel flowmeter that utilizes

hybrid technology to handle both low flows and medium to high flowrates.

Called the Cartridge Meter, Eastech’s open channel flowmeter is a highly

efficient combination of a trapezoidal flume, ultrasonic level sensor and

a pair of transit-time velocity sensors. When the media occupies the

initial 33% of the conduit, flow is measured by the trapezoidal

flume/level sensor combination traceable to Bureau of Reclamation WinFlume

standards. When flow increases above the 33% level (referred to as the

Crossover Point), it is measured by utilizing the same ultrasonic

level sensor, except it is now operating in conjunction with the +/- 2%

accurate transit-time velocity sensors. Combined overall accuracies of +/-

5% are achieved with corresponding turndown ratios of 60 : 1.

Eastech

Flow Controls has introduced an open channel flowmeter that utilizes

hybrid technology to handle both low flows and medium to high flowrates.

Called the Cartridge Meter, Eastech’s open channel flowmeter is a highly

efficient combination of a trapezoidal flume, ultrasonic level sensor and

a pair of transit-time velocity sensors. When the media occupies the

initial 33% of the conduit, flow is measured by the trapezoidal

flume/level sensor combination traceable to Bureau of Reclamation WinFlume

standards. When flow increases above the 33% level (referred to as the

Crossover Point), it is measured by utilizing the same ultrasonic

level sensor, except it is now operating in conjunction with the +/- 2%

accurate transit-time velocity sensors. Combined overall accuracies of +/-

5% are achieved with corresponding turndown ratios of 60 : 1.

According to Frank Sinclair, president of Eastech:

The cartridge design, with its integrally mounted factory-pre-aligned sensors, can make installation faster and safer than a device with multiple parts, and can reduce maintenance requirements over the life of the flowmeter.

He also notes that the Cartridge Meter is self-cleaning, further reducing the need for labor-intensive post-installation maintenance. The Cartridge Meter can be installed in 30 minutes.

Eastech has two models:

Model 7100 Cartridge Meter – a basic model for flows that do not exceed the maximum flow capacity of the trapezoidal flume

- Model 7200 Cartridge Meter – a more advanced model using two velocity sensors that measures flow regardless of liquid level, direction, or surcharge conditions

Eastech Flow Controls is the successor to Badger Meter’s ultrasonic flowmeter division. It is exciting to see some new and innovative technology applied to the area of open channel flow measurement. We will continue to monitor the progress of Eastech’s Cartridge Meter, and that of other participants in this market.